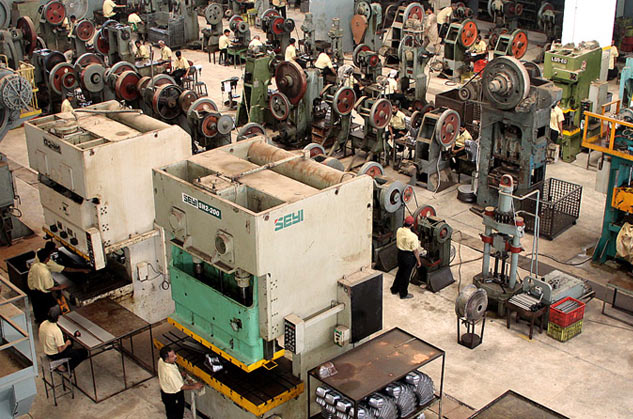

Stamping Facilities

We have Pneumatic, Hydraulic and Power Presses ranging from 10 Tons to 500 Tons. This stamping shop is producing a variety of parts for motorcycle and cars automobile industry. Our stamping shop is producing a huge quantity a month with the help of a great range of presses.

The variety of components comprise of inner body and engine parts like Center Pillers, Frame Roofs, Oil pans, Housings, Reinforcement Panels and tube assembly etc.

Welding Facilities

We have dedicated and separate assembly lines for different components of Cars and Motorcycles including Swing arms, Main Stands and Front Fork Covers, which are being manufactured and supplied to OEM’s with the following Welding facilities.

- TIG Welding.

- MIG Welding.

- Spot Welding.

Robotic Welding Facilities

With a vision to remain model of excellence and to achieve we are continuously improving our production facilities. We always try to be on top when it comes to usage of state-of-the-art Technologies. We have upgraded our Welding facility by installing 6 New “Robotic Arms” which are capable to deliver the best welding services and ultimately to manufacture a best quality components. The robots have already started the manufacturing and we take this pride to be the pioneers in installing this facility at BEI. This advancement has made us more capable to provide quality products with lesser production time and greater customer satisfaction.

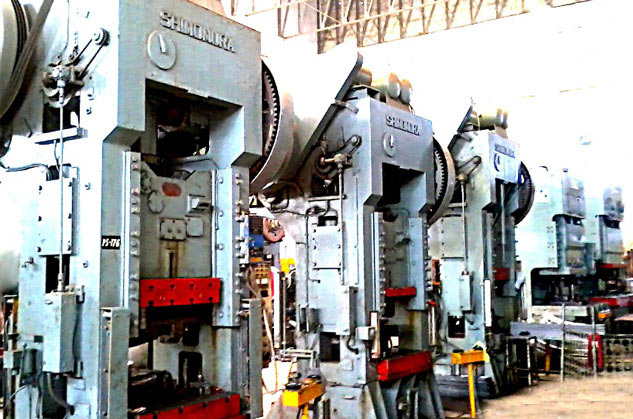

Forging Facilities

The manufacturing of Forged Automotive components for OEM’s is being carried out on our 600 tons brand new Forging Press Line. This line was imported and installed by the experts from Taiwan.

This forging line is complemented by Shot Blasting Machine, Electrical Induction Heating Furnace.

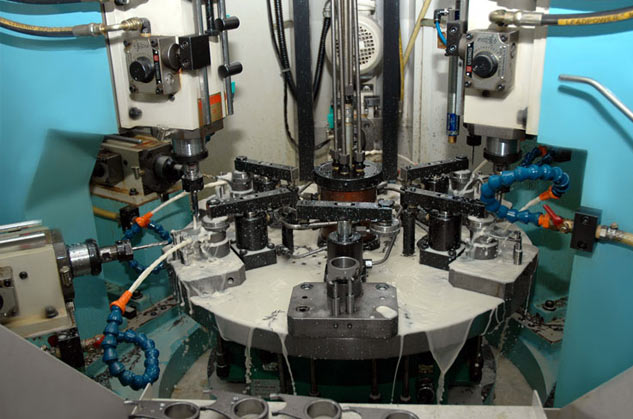

Machining Facilities

We have well equipped and managed Machining Production Facilities looked after by experienced and skilled workers.

This machine shop is equipped with CNC Turning Centers and NC Special Purpose Machines, which are producing mass quantities of different types of Machining Components.

These machining components includes most importantly the engine components like Clutch Lever and Drum Assembly for motorcycles with high precisions.

Painting Facilities

Our Paint shops compliment our products by producing the best quality painting works; to do in-house painting according to the requirement of our precious customers, our Painting Lines comprise of Phosphating and Degreasing facilities and Baking oven is a part of this process to further add value to the parts.

Engineering Development Facilities

The Engineering and Development department is fully equipped with modern and conventional, machines including Machining Centers, Wire Cuts, EDM’s and Copy Milling etc.

This ensures that we are self-sufficient in all departments of manufacturing.

All the Sheet Metal and Forging dies are being manufactured right from the beginning i.e. CAD data till the CAM and assembling of Dies.

Our experienced work force are able to handle CAD data and also do reverse engineering.

We develop in-house Moulds and Dies with the philosophy of “Quality by design”.

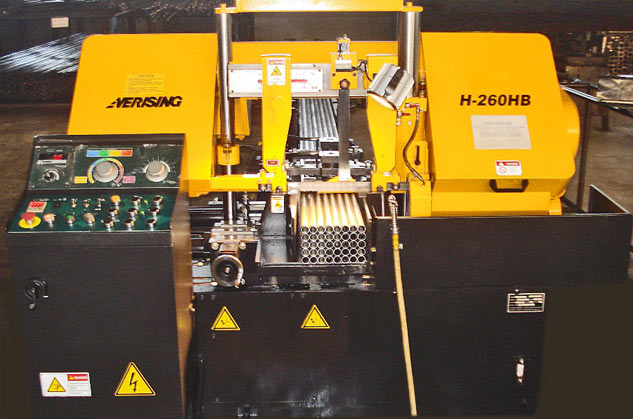

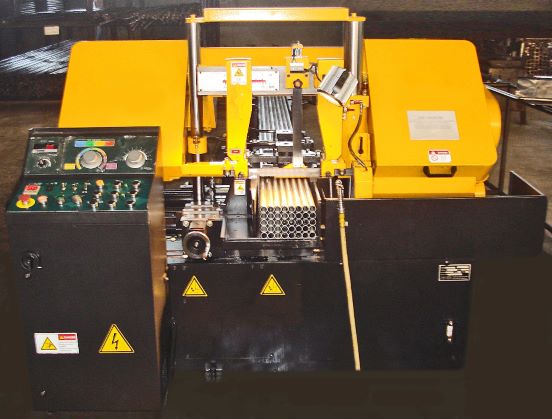

Shearing Facilities

We pride ourselves on providing top tier shearing services that meet the highest industry standards. Our cutting-edge equipment and skilled workforce ensure precise and efficient shearing of various materials. Whether you need sheet metal, or any other materials sheared to perfection, our facilities are equipped to handle your requirements with precision and reliability. Trust us to deliver quality results, tailored to your specifications, every time. Experience the difference with Brothers Engineering Industry’s shearing facilities.

Quality Assurance

We are committed to produce those products which fit to customer requirements and putting efforts to ensure fail-safe production processes. Customers may be sure of that we are having Quality Assurance philosophies well in the organization.

A separate Quality Assurance department is fully functional and equipped with modern necessary equipment and experienced team.

We carry out inspection at various stages to ensure the delivery of quality products to our precious and valuable customers.

- In-Coming Inspection: We inspect all the in-coming materials and parts thoroughly.

- In-Process Inspection: our Quality Executive thoroughly inspects the products during its production processes.

- Final Inspection: takes place before supplying it to our precious customers.

That shows our commitment, that how much conscious we are about the quality of our products.

We have increased focused on the Quality Assurance side by setting up a Quality Lab to strengthen our quality standards by adding the following machines:-

- Digital Display Rockwell Harness Tester HRS-150

- Metallographic Microscope Transmitting & Reflecting XJZ-9

- Coating Thickness Tester TT-220

- Ultrasonic Flaw Detector CTS-23A

- Profile Projector JT-12A

- Digital Display Hydraulic Universal Testing Machine WES-330B